|

by Ronald D. Noebe, Ph.D. and Mark McDowell, Ph.D. |

|

by Ronald D. Noebe, Ph.D. and Mark McDowell, Ph.D. |

More homeruns hit than ever before!

Games taking longer to play!

It Must Be The Bats?

There is no doubt that softball bats today are highly engineered "tools" made out of sophisticated lightweight structural materials with the sole purpose of propelling a ball faster and farther than ever before. Bats get all the press and therefore, all the blame. But there has been a more insidious change in equipment that has been mostly overlooked, and yet can impact the game much more than the bat- It's THE BALL!

Nevertheless, softball associations have

focused their attention on bat performance testing and stricter regulations

(more on this in future articles), while softballs have received much less

scrutiny in recent years. Current softballs are very simple yet efficient

pieces of equipment, (see Figure 1 - Parts of a Softball). They consist

of three basic parts. A leather or synthetic cover, a raised stitched seam,

and a solid polymer (polyurethane) core. It is this solid polymer core

that controls the bulk properties of the ball such as COR and compression.

Figure 1 - Parts of a Softball There are only three parts to a softball: the cover, the stitching or seam, and the core. The purpose of the cover is to appeal to the senses. It should make the ball easy to spot and easy to grip. In terms of performance, it doesn't matter whether the cover is synthetic or leather. Synthetic covers are usually more consistent (do not contain the defects found in natural leather) and are less impervious to moisture; however, most people prefer the "feel" of leather. The stitching or seam is actually more important to the performance of the ball. The raised stitches create turbulent flow of the air around the ball, reducing resistance as it travels through the air. This allows the ball to travel farther. Similar to the way dimples act on a golf ball. If the softball were perfectly smooth it would travel only about half as far when batted. The other purpose of the stitching is to distinguish or identify the ruling softball association. USSSA softballs have blue stitching and NSA balls have black stitching. ASA 0.47 COR balls are red stitched and their .50 COR balls have white seams. Finally, 0.44 COR balls, regardless of association, have gold stitching. The final "part" of the softball is the solid polymer core. Cores today are made out of a very common and tough polymer known as polyurethane and are produced by injection molding. This solid core determines the bulk properties of the ball, which are discussed in further detail in the main article. The only 12" softball that does not contain a "poly" core is the Dudley SB12, which still uses a cork core. |

A regulation men's softball should be 12 +/- 0.125 inches in circumference (or approximately 3.8" in diameter) and can weigh between 6 and 7.25 oz. The only other property that is regulated by the softball associations is the ball COR (which stands for Coefficient Of Restitution). COR is a measure of ball performance, or what some people refer to as the "liveliness" of the ball. The most common COR ratings for softballs are 0.44, 0.47, 0.48 and 0.50. These numbers represent the square root of the fraction of incident energy retained by the ball after a collision with a static and immovable object. Therefore, a COR rating of 0.50 means that 25% of the energy involved in the collision between a ball and a static object was lost to inelastic processes such as deformation, heat, and vibrational noise.

In Simple terms, the COR can be defined

and measured as the ratio of the rebound speed of the ball bouncing off

of a rigid wall compared to the ball's incoming speed.

| COR = Rebound ball speed

Incoming ball speed |

Typical softball players can generate a bat speed of 60 - 80 mph. Therefore, a ball's COR (as dictated by the ASTM test standard) is measured using an incoming ball speed of 60 mph. A ball cannon is used to propel the ball against a wall at 60 mph and the speed that it bounces off the wall is measured using a light trap. If the rebound speed is 30 mph then the COR rating would be 30/60 = 0.50. The bottom line is that the larger the COR rating the faster the ball will leave a bat when hit and therefore, the farther the ball will travel.

Another property of the ball that has as much, if not more, affect on performance is the core hardness or compression. This is currently an unregulated property, though ASA will begin regulating ball hardness starting in 1999 [ASA Regulation Link]. However, they have not yet determined what hardness level they will consider acceptable.

For softballs, hardness is defined by the ball's compression, which is determined by measuring the force in pounds necessary to deform a softball in compression by 0.25". Not that long ago, all softballs contained cork cores with a compression of around 250 lbs/0.25". That was back when the term "softball" was actually an appropriate description. In the mid-1980's they started replacing the cork core with a polyurethane core (See Figure 1 - parts of A Softball). This gave the materials engineers something to manipulate. Polyurethane, can be crosslinked in a two-step polymerization process. Crosslinking allows long chains within the polymer network to bond together in many places along the length of the chains causing a tighter network. This causes an increase in hardness or ball compression. At the same time, materials engineers are able to keep the COR value the same so that the balls are "regulation". However, the hardness has been rapidly increasing to the point where 500 lbs/0.25" balls are now common and 650 lbs/0.25" balls were used in certain tournaments last year.

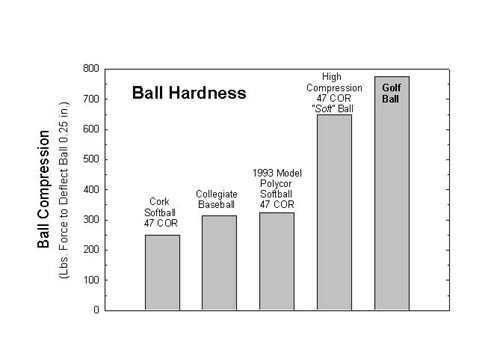

Consequently, today's "softballs" have more

in common with a golf ball than they have in common with their earlier

predecessors. As shown in the Figure 2 (Ball Hardness vs Ball Compression)

below, today's high compression softball is only 16% softer than a golf

ball and 200% harder than a collegiate baseball (usually referred to as

a "hardball"). So if you thought that the last line drive to catch you

in the shin hurt more than usual, there is probably a very good reason

for it.

Figure 2 - Ball Hardness vs Ball Compression |

Remember that the ball COR was measured by shooting the softball at an immovable object, usually a 2" thick steel plate mounted rigidly to a wall. But your softball bat is not an immovable wall. It is a thin-walled flexible tube, designed to return energy as efficiently as possible. Consequently, when a ball hits the bat you get deflection of the thin wall, which is referred to as the "trampoline" effect and you may get deflection or bending in the handle, which is referred to as the "springboard" effect. As both of these terms imply, you are returning more energy to the ball by making the bat-ball collision more efficient.

But what is the relationship between these energy return processes and ball hardness? Well, the harder the softball the more elastic deflection you will get in the bat, increasing the so-called "trampoline" and "springboard" effects. Thus returning more energy or speed to the ball. For example, a ball of yarn looks the same to your bat as a softball might appear to a stationary wall. But as you increase the hardness of the ball, your bat starts responding more to the bat-ball impact by deforming elastically and returning that elastic energy back to the ball. Therefore, a harder ball will tend to come off of a bat faster and travel farther. The downside is that if the ball is too hard, the bat will also deform inelastically, which leads to denting.

Before we can quantify the effect of ball compression on performance we need to define a few more terms. Similar to the ball COR rating that was measured against a wall, there is term referred to as a bat-ball COR, which is a measurement of the Coefficient of Restitution of the bat-ball collision and is determined by shooting a softball at a mounted bat. However, the measurement and calculation of this quantity is not as straightforward as the simple ball COR. We will leave these details for a future article, if there is enough interest. Nevertheless, the bat-ball COR value is dependent both on the COR value of the softball and the hardness of the softball, because what the bat-ball COR essentially measures is the so-called trampoline and springboard effects.

The bat-ball COR is also used to define

the BPF rating of a bat. The Bat Performance Factor (BPF), may be a complicated

thing to measure (because of the determination of the bat-ball COR value)

but it represents a simple concept. It is a ratio between the bat-ball

COR and the ball COR.

| BPF = bat-ball COR

ball COR |

For example, if you assume a ball COR of 0.50 and your bat has 1.2 BPF, then the bat-ball COR would be 0.6. The real irony is that according to the ASTM standard for determining the BPF, the ball used for testing must have a compression of 350-375 lbs/0.25" and a COR of 0.47. But that is no longer the compression value for balls used today! Ball compression is actually much higher.

Nevertheless, we can actually quantify (measure) the effect that ball hardness has on the performance of a bat. We have obtained data taken of a bat that met the 1.2 BPF standard with the ball specified in the standard and then ran the tests again using balls with a higher compression (but still 0.47 COR). These higher compression balls would be more consistent with the balls actually used today. From these tests a ball with a compression of 425 lbs/0.25" increased the BPF measurement to 1.26. And a ball with a compression of 535 lbs/0.25" resulted in a BPF measurement of 1.29!! If this data extrapolates linearly, then the high-compression 650 lbs/0.25" tournament balls would result in BPF of 1.35!! So in reality, your bat stamped 1.2 BPF is really equivalent to about a 1.3 BPF bat because of the type of balls used today. In other words, the ball manufacturers have defeated the regulations placed on bats by changing the balls!!!

By using a series of equations that are

provided in the proposed ASTM "Standard Test Method for Measuring Softball

Bat Performance Factor" you can calculate the batted ball speed as a function

of ball COR and the BPF. In order to see how ball hardness actually affects

performance we have performed some of these calculations for the various

compression balls using the respective BPF values measured and assuming

an average swing speed of 60 mph (for an average player) and 80 mph (for

a superplayer) This data is included in Table 1, along with the time it

takes for the ball to reach the pitcher. Remember that all the data in

Table 1 is for the same bat, the only thing to change is the ball hardness.

|

Effect of Ball Hardness on BPF, Calculated Batted Ball Speed, and Time

for the Ball to Reach the Pitcher's Mound (Pitcher Reaction Time)

|

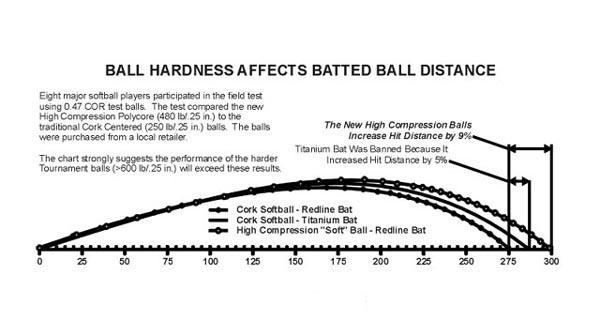

The data indicates that all other factors

being equal a change in ball compression from 350 to 650 lbs/0.25" results

in a 4.8% increase in batted ball speed. This may not seem like a large

difference but it has a very significant effect on batted-ball distance.

The 3.4-mph increase in batted-ball speed, due solely to increasing ball

compression from 350 to 650 lbs/0.25" for a 60 mph swing speed, is equivalent

to about 17 extra feet that the ball will travel!1 Titanium

bats were banned for increasing batted-ball distance by only about

10-15 feet! (see Figure 3 - Ball Hardness Affects Batted Ball Distance)

So obviously, something has gotten out hand.

Figure 3 - Ball Hardness Affects Batted Ball Distance |

Due to a lack of control on ball hardness, ball manufacturers have manipulated hardness in order to gain a competitive advantage over each other in marketing the most "lively" balls. This has resulted in terrific changes to the sport of softball over the last few years. In fact, performance increases in the game can be linked more to changes in the ball than the bats.

Unfortunately, the increase in softball compression has negatively impacted the game of softball in a number of ways. First, by circumventing the present regulations that attempted to place BPF limitations on bats, batted-ball speeds have increased, decreasing the time players have to react to the batted ball. This increases the chance for injury. Not only that, but the injuries will tend to be more severe. These balls are now twice as a hard as baseballs. And because the balls are harder they will naturally do more damage to the human body on impact (not to mention all the dented bats you will go through this season). Finally, because of the significant increase in the distance the balls travel, a record number of homeruns were hit last year in all divisions, significantly increasing the time required to play games. Therefore, instead of making the game more exciting, (except for the increased injuries), these harder balls have slowed the game down.

Things have obviously gotten out of control. Yet it makes no sense to place further limits on bats, especially without fully controlling ball properties, namely hardness. Unfortunately, not all the associations see it that way. In fact, your new $200-$300 bat may become illegal in a few years if the ASA adopts its proposed legislation to have bats meet the 1.2 BPF using balls with a compression of 625-675 lbs/0.25". As we have demonstrated above, all bats that are today stamped 1.2 BPF would measure over 1.30 BPF using the higher compression balls. Thus every bat on the market today would be illegal under these new rules!

This makes absolutely no sense. Especially when the solution to this problem is quite simple: limit ball hardness to the level prescribed in the original BPF testing requirements, 350-375 lbs. as a maximum value, and leave the bats alone!!!

| Acknowledgements: We would like to thank Dr. Dewey Chauvin of Easton Laboratories for taking the time to educate us on this topic and Dr. Anita D. Tenteris-Noebe for her extensive effort in editing this article and researching this topic. |